Tank Storage Terminals

We have 200+ bulk liquid tanks, ranging from 150m3 to 100,000m3 to store everything from LPG to Crude, Bio Fuel, Bitumen and more. Thanks to excellent road, rail and water links along with connection to the UK Oil Pipeline (UKOP) and Manchester Jet Pipeline. With a draft of up to 14.3 metres, the Tranmere site can be utilised to receive larger vessels carrying up to 170,000 tonnes of crude oil.

Our terminals offer reliable storage for any kind of chemicals, biodiesels, base oils and lubricants in large or small quantities, in stainless steel, coated or mild steel storage tanks. you can be assured that will always have the perfect solution for your specific needs, because of the storage capacity tanks we have virtually in every size.

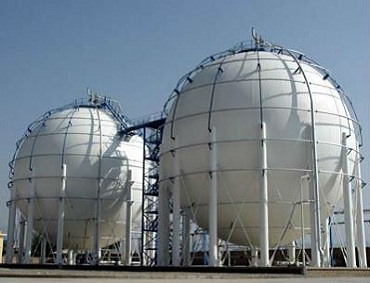

Tank Farm

In the past year, we became one of the world’s top storage companies in this competitive field.

The company clients include private and state oil companies, refiners, petrochemical companies, and traders in petroleum products and chemicals.

Our staffs have good orientation towards customer relation and satisfaction; the company develops and operates business with reputable domestic,

private and state-owned companies, whereby acting as operating partner in the joint venture.

Sea Bunkering LTD perform vital connecting services through the storage of oils, chemicals, gases,

for the world’s oil fields, oil producers, oil suppliers, oil purchasers, users of derivative products and independent terminal operators, independent storage terminals,

the company employs a decentralized management structure in which each of our storage facilities functions effectively to the utmost satisfaction of our clients.

The size of the tank is determined by the design requirements of pipeline and refinery customers.

Our Tank Farm Facilities and terminals are strictly regulated and must comply with comprehensive Transportation requirements that govern everything from design,

maintenance, and size of tanks; to safety measures including containment; to regulations for air quality and other environment permitting our tank farm are well-maintained facilities that have been designed, built, and located to minimize public impact.

The tank farm facilities are secured and fenced, with lighting designed to provide security yet minimal disturbance to neighbors, and as part of an interstate transportation system.

Among other integrity testing, new tanks are filled with water and monitored for potential leaks during hydrostatic testing prior to being placed into service.

In addition, cathodic protection provides corrosion control as normal operations are engaged.

Tanks are also grounded to minimize static electricity build up during filling and refilling, and to redirect lightning strikes, should any occur.

All of our facilities are routinely monitored, inspected and maintained.

Trained terminal personnel complete a visual inspection of every tank at least monthly.

Additional annual inspections are also performed. we support the efforts of safely and reliably delivering petroleum products to refineries tankers vessels and our other clients to make into products we all rely on every day.

Our terminals serve as oil bunkering and oil handling to vessels in our different port of operation.

Our storage facilities include; Bitumen storage tanks, Fuel oil storage tanks, LPG storage spheres, Crude oil storage tanks, Biofuel storage tanks, Petrochemicals storage tanks, Aviation jet fuel storage tanks, Petroleum product storage tanks, Base oil and lubricant storage tanks.

Terminals

Rotterdam Terminal

Our company has a subleasing tank storage facilities from major company at Rotterdam Terminal Port complies with the international standard directive, which means an extended safety management system audited annually by the local authorities. We elected to have a valuable system for all its tanks. This means that the storage capacities of all the tanks with strictest regulations. The terminal is designed for easy shipment assessment on export of oil products.

Houston Terminal

For our customers in the United States, North America, and Central America, our Houston Port storage facility is ideal. Our complex petroleum tank terminals, which include pressurized tanks, nitrogen compensation systems, and a sophisticated vapor return scheme. The storage tank's terminal houses three distinct multi-purpose distillation units. We offer exceptional storage, transfer, and distribution services at the Port of Houston.

Jurong Singapore Terminal

Our Jurong Terminal offers a world-class storage solution for liquids in one of the world’s leading chemical and energy hubs. With a strong reputation for reliability, efficiency, and safety, our terminal has established itself as a trusted partner for the storage and handling of various liquid products. At our Jurong Singapore Terminal, we prioritize safety, efficiency, and customer satisfaction. Our first priority is to render our good services to our clients at all time.